|

The purpose of a controller is to regulate the temperature

of a heating device either at a fixed point or as a controlled ramping change from one

temperature to another over minutes or hours. Most glass studios

have several controllers for the heat supplied to annealers,

color kilns, and furnaces and these may be combined in one electronic unit or be

separated. A controller may include safety

features required by either the electrical code (NEC) or one of several fire codes

and thus cost more.

|

||||||

|

Choices (and history) in Temperature Controllers for Glass By Mike Firth Rev. 3/13/97, 2/18/98, 2000-8-20 Controlling temperature for melting glass and annealing it has used a number of devices historically and has seen great improvement in the last few years. Electric melt and annealing control is relatively easy, but limited in quantity and maximum temperature; while adding control to gas furnaces jumps the cost. One ongoing problem is the need to accurately control the fall of temperature in the annealer over many hours. Temperature control can take two forms, open loop and closed loop. In an open loop, a device controls the heater, thus raising or lowering the temperature, but the temperature does not affect the device. In a closed loop, the measurement of the temperature modifies the behavior of the device in controlling the heat. A resistance control, dimmer or Variac (variable transformer) is open loop; modern controllers are closed loop. To quickly summarize the following, open loop devices were first used, then as microcomputer technology began in the 70's, fairly expensive controllers that used closed loops were available. Then the cost started coming down and a series of multi-step keypad programmed controllers, such as Digitry, came on the market. Most recently, controllers that "learn" the characteristics of the furnace or annealer and adapt for better control have come on the market. Some of these have computer ports so that control can be maintained on a computer screen. And now we are seeing multiple ramping units at relatively low cost (under $200.) In glass working, the chief open loop devices have been the food cooking oven controller, variations on dimmers, and the variable transformer (Variac, a brand name.) In each case, if a roughly constant temperature is wanted, the human adjusts a knob until it is about right. Most retail dimmers do not have anything like enough capacity to control an annealer; but a dimmer can control a heavier triac or it is not difficult to build a 25 amp dimmer (or bigger.)* Oven controls used are variable resistors, like on home ovens, which are easily available and have the capacity but waste energy and are not very sensitive.

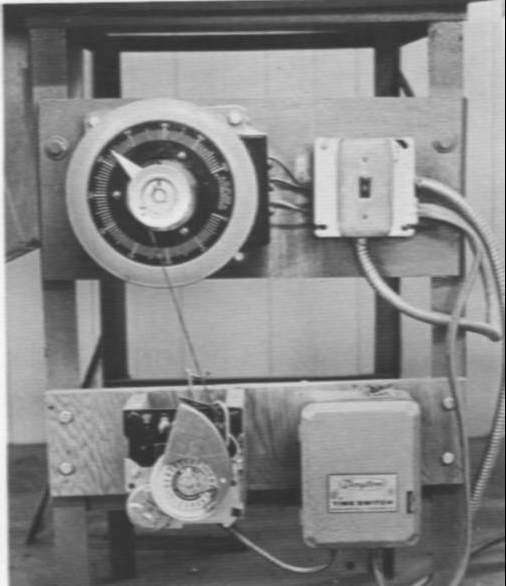

The Variac was mounted on a board with a 24 hour timer whose purpose was to provide a very slow motor. On the shafts of the timer and transformer were mounted disks or segments around which string was run from one to the other. As the timer dial turned, the Variac dial was dragged along, slowly lowering the voltage. Some people used cam shaped disks, so the Variac moved more slowly during the first hours and faster during the later ones. Some of these are still in use, I saw one at John Littleton and Kate Vogel's studio in 1995. As the voltage fell, the power fell as the square of the change and the temperature fell accordingly. But the temperature curve was only monitored by a human and did not affect the timing of the process. (Image shows Harvey Littleton's Variac controller from his book.) Recently, exactly the same thing can and has been done for a few dollars and it is one better than Variac. Peet Robison in New Mexico built a controller in which comparator chip compared the amplified voltage from a thermocouple to the output from an digital to analog converter (DAC) turning on a triac controlling the heating element when the thermo voltage was lower than the DAC. The DAC setting was controlled by a small counter that changed every few minutes. The total parts cost is about $8 for building this. Note that it is closed loop, because the temperature reading influences the comparator, but what is being controlled is some arbitrary number not a precise temperature. Also the temperature curve is straight line, which is an improvement, but not the best. Today, for $12.50, a chip is available which corrects for oddities of a K-type thermocouple, so the output is (within a small percentage) a voltage the same as the temperature (6.55 volts = 655.C) and thus finer control is possible. DIGITRY - The most widely used controller in glass

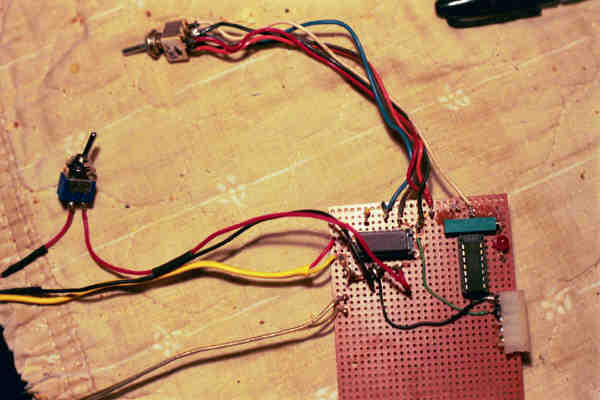

melting and annealing is probably Two new technologies are available for control. One is a self contained unit that will provide a single or multiple ramp and learn the characteristics to the controlled unit. [These can look like the two upper units in the image.] The other is using a computer to control the controller. Actually, the first units can be had with an option that allows computer control of changing the ramp and then letting the unit run. Several companies have come to market with small (2" x 2" x 4") controllers for about $200 that avoid a complication that has plagued controllers for years. PID (Proportional-Integral-Derivative) is a method that allows programming controllers so they do not overshoot their goal or over-control, wasting energy. Unfortunately, PID requires careful selection of parameters to match the furnace/annealer to the heat source. This is eliminated in the new units because they "learn" the characteristics of the equipment, adapting to different building temperatures, etc. I have an annealer with a low wattage light bulb across the elements that goes on and off with the elements. It is easy and fun to watch as the controller turns on the element and, after the temperature has risen, turns it off to see how much coasting goes on. After testing, the unit finally runs the temperature right up to the setting. A $300 solution involves buying a CN76000 Auto-Tune Controller (dc pulse output with alarm option, CN76120, $195 or adding remote setpoint option, CN76120-SP, $234, page P-95) from Omega (1-888-TC- OMEGA, ask for the Temperature Handbook, www.tcomega.com ), along with a K-type thermocouple, DH-1-8-K-12, $19, (page A-13), 25 feet of K type thermocouple wire, PR-K-24, $15, male and female K-type miniature plug connectors (SMP-K-MF $4, page G-16) and a Solid State Relay SSR240DC25 (DC control voltage, 25 amps, up to 280 Volt) $26 + Heat Sink FHS-2, $17. There are only 3 pairs of wires to hook up - AC power, thermocouple, output. [Controller Comparison] AD595 - There is a set of Analog Devices chips that will take a K-type thermocouple and produce a 10 mv reading per degree C or produce a setpoint controller. With a fairly simple switch, a single chip can do either. I paid $12.50 a chip (buying 2 to meet $25 minimum from Newark Electronics, current suggested retail for quantity 100 is $7.28. Data Sheet PDF on 2012-10-18

The two chips shown above are designed to have a K-type connected to the pins at one end (pins 1 and 14/8). For the reasons given in the discussion of thermocouple connections, AD recommends making heavy copper connections to these two pins showing wide foil connections on their PCB layout. I used a wire wrap socket and bent the pins over to make the solder connection rather than use smaller wire. All this is to keep the connections as close to the chip temperature (which is measured by ICE POINT COMP) as possible. I solder a short length of thermocouple connection wire to the PCB and put a mini-connector on the end of that. Circuit to be tested and posted soon. (he said on 9/20/2000)

2002-11-04 I got the thing working, after redrawing the schematic from the bottom and tracing all the wires. There was not a good connection at the measuring point. The core problem was that the measuring points were not connected reliably. I tore off the wires and removed the Molex. Finding nothing smaller, I used two terminals of a European style terminal strip. Once firmly connected, it seems to work well at light bulb temps. Will test with one of my boxes when it isn't raining and I am awake.

|

the

the

This is the circuit for using the AD595.

As shown in the diagram, a DPDT switch allows choosing between

measuring temperature and checking the set point. A digital volt

meter connected to TP (Test Point) and ground (GND) will show 0.001

volts per degree Centigrade (1 mv/C) I use a multi-turn

potentiometer. A limitation of the chip is that it will only

drive 5 ma. There are opto-isolators that will work with that

drive level, but only just barely. So gates are added and the

easiest to get are inverting. Although hard to see, the three

gates are Schmidt Trigger inverting gates (3 of 6 in a 74H14) because

the signal changes slowly and CMOS usually doesn't like slowly

changing signals. [2002-10-26 I had kind of let this circuit lay around for a

while, but got bugged and today realized I might need a pull-up resistor.

When I began looking for specs, I was dismayed to find that the 74HCT14 from

Radio Shack are very limited on voltage range because they are to work with TTL. So

my whole reason for choosing CMOS - voltage variability - is voided because I

didn't know/look at the specs. Now to find one cheap/quick.]

This is the circuit for using the AD595.

As shown in the diagram, a DPDT switch allows choosing between

measuring temperature and checking the set point. A digital volt

meter connected to TP (Test Point) and ground (GND) will show 0.001

volts per degree Centigrade (1 mv/C) I use a multi-turn

potentiometer. A limitation of the chip is that it will only

drive 5 ma. There are opto-isolators that will work with that

drive level, but only just barely. So gates are added and the

easiest to get are inverting. Although hard to see, the three

gates are Schmidt Trigger inverting gates (3 of 6 in a 74H14) because

the signal changes slowly and CMOS usually doesn't like slowly

changing signals. [2002-10-26 I had kind of let this circuit lay around for a

while, but got bugged and today realized I might need a pull-up resistor.

When I began looking for specs, I was dismayed to find that the 74HCT14 from

Radio Shack are very limited on voltage range because they are to work with TTL. So

my whole reason for choosing CMOS - voltage variability - is voided because I

didn't know/look at the specs. Now to find one cheap/quick.]

To

the right is a second power control cable built the same way as the one above,

except that the SSR is controlled by 120 VAC like the one below instead of

5 VDC. So the cord from the control terminals ends in a common 120 plug

instead of phono plug. I use this to control a second element in my

annealer when I want to take it up to 1450F or so instead of no higher than

1100F. The main element is on the lid and the second is the original hung

around the top of the sides, which is actually broken and just hooked together.

There is a low wattage standard light bulb indicating power on for the main

element. Unscrewing this bulb and adding a common socket adaptor lets me

plug in this control to a second power source (an extension cord when I need it)

rather than rewiring to handle 20+ amps that both circuits would pull together.

2005-05-10

To

the right is a second power control cable built the same way as the one above,

except that the SSR is controlled by 120 VAC like the one below instead of

5 VDC. So the cord from the control terminals ends in a common 120 plug

instead of phono plug. I use this to control a second element in my

annealer when I want to take it up to 1450F or so instead of no higher than

1100F. The main element is on the lid and the second is the original hung

around the top of the sides, which is actually broken and just hooked together.

There is a low wattage standard light bulb indicating power on for the main

element. Unscrewing this bulb and adding a common socket adaptor lets me

plug in this control to a second power source (an extension cord when I need it)

rather than rewiring to handle 20+ amps that both circuits would pull together.

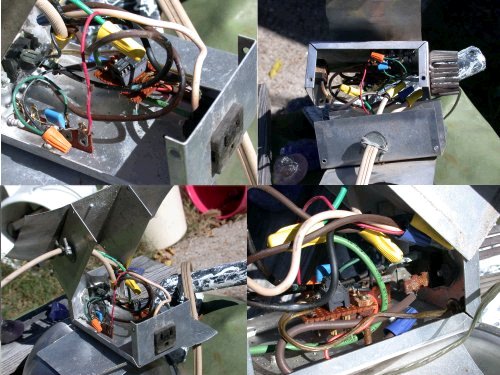

2005-05-10 as well as the edge view of the adaptor

mounting plate. The lower right image shows the face of the surface mount

outlet and a different view of the plate, while the lower left shows the two

solid state relays and the wiring coming out of the outlet. I use RCA phono plugs to plug in the 5 vdc controls and this is shown in the middle with

the wire leading to the relay.

as well as the edge view of the adaptor

mounting plate. The lower right image shows the face of the surface mount

outlet and a different view of the plate, while the lower left shows the two

solid state relays and the wiring coming out of the outlet. I use RCA phono plugs to plug in the 5 vdc controls and this is shown in the middle with

the wire leading to the relay.

In

the schematic at right, taken from

In

the schematic at right, taken from