Return to Sitemap

2006-01-11 Rev.2006-02-25, -07-07 2008-04-08

![]()

|

Pressure and flow of fluids are interrelated and many points of design are similar to voltage and current with electricity. In both cases it is possible to "get away" with choices that work until a design needs to be near the limits at which point parts of the system don't work or interfere with settings on other parts. It is better to be sure. Pressure is force per area and in American usage is commonly measured in pounds per square inch (psi) Under metric measure the unit is the Pascal which is Newtons per square meter. (See table below.) The diameter of pipes becomes significant when the pipe is being branched off

to feed various sources. You then want to start with large pipe (lets say 3" for

air from a blower) and when you feed some off (maybe an 1-1/4" pipe), you want to reduce

the size of the main pipe also (to maybe 2".) This keeps the pressure up

in both the line and the side feed. The same thing is done with water as in

sprinkler systems and in gas with multiple appliances. Plumbing supply

places and sites will have pressure drop information. Full service

software for fluid systems is complex and valuable and thus expensive, as these

sites will suggest:

Flowmaster - Fluid thinking for systems engineers ,.

Pipe Flow Software -

Pressure Drop and Friction Loss Calculations or

Elite

Software - S-Pipe . For a discussion of home plumbing see

Properly Size Your Water Lines

|

|

Here are more examples of problems: |

Pressure and flow are interrelated in the following way:

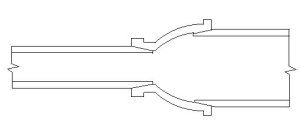

Here is a section of pipe with a bell joint so the pipe gets larger if the flow

is from left to right. Liquid can not expand or

contract so how is the space created to be filled? The fluid slows down,

losing pressure.

Here is a section of pipe with a bell joint so the pipe gets larger if the flow

is from left to right. Liquid can not expand or

contract so how is the space created to be filled? The fluid slows down,

losing pressure. [Wait a minute, isn't it true that hydraulic jacks work because liquids pass pressure/force through them? Yes, but that is static force. Here we are talking about dynamic forces - flow of fluids.] Friction on the walls of the pipes and from turbulence going around bends prevents the pressure applied to the beginning of a system from being maintained to the end. Lets suppose a pipe system is 100 feet long, 1/4" inside (small), and is filled with water. Pressure at the beginning is 20 psi and because liquids are not compressible (much) the pressure is the same throughout when nothing is flowing. This is called static pressure. If we quickly open a valve at the other end, the pressure will start falling and fluid will start flowing. |

| Pipe Sizes The table at right shows the ID and area of standard water pipe with a column showing the proportion of each size to common 1/2" pipe. This shows reasoning behind the common arrangement of a 3/4" pipe (ratio almost 2) feeding two 1/2" pipes. Similarly, a 1" line is commonly required for 2 three-quarter inch lines (2.84:1.75) or 3 half inch lines (2.84:1). In the situation where all the lines are flowing, the water is (just about) evenly divided between the lines and pressure is even between them. |

|

|

PRESSURE UNITSBecause pressure is so widely used there are several different measurement terms in use mostly for the convenience of the user. The most direct American measure is pounds per square inch (psi) and the matching metric measure of Newton's per square meter. Most of the variations result in a simple small number for everyday use. |

|

|

|

psi |

Pa |

kPa |

MPa |

bar |

mbar |

Torr |

atm |

in Hg |

WC* |

|

|

1/4 |

1.724 |

7 |

Household delivery pressure |

|||||||

|

1 |

6895 |

6.895 |

0.0689 |

68.95 |

0.069 |

2.036 |

27.71 |

One pound per square inch, conven.28"H20 |

||

|

2 |

13.8 |

0.138 |

Glass studio higher pressure |

|||||||

|

14.502 |

100.000 |

0.1 |

1 |

750 |

0.987 |

29.53 |

401.86 |

One atmosphere, about, exact kPa |

||

|

14.696 |

101,326.2 |

101.325 |

1.0125 |

1013.26 |

760 |

1.000 |

29.92 |

407.22 |

One atmosphere, exact definition |

|

|

25 |

172.4 |

Convenient pressure |

||||||||

|

145.03 |

1,000,000 |

1,000 |

1 |

One mega Pascal |

||||||

|

60 |

413.7 |

High pressure local distribution |

||||||||

|

psi is American unit of pressure measurement, pounds per square inch |

||||||||||

|

Pascal, metric unit of pressure measurement, Newtons (force) per sq. meter |

||||||||||

|

kPa, common metric measure, convenient size units |

||||||||||

|

MPa, More rarely used metric measure because so large |

||||||||||

|

bar, weather, starting with one average atmospheric pressure |

||||||||||

|

convenient units size |

||||||||||

|

Torr, weather |

||||||||||

|

atm, one average pressure of air |

||||||||||

|

weather, USA |

||||||||||

|

|

WC, Water Column height in inches cheap way to measure low gas pressures | |||||||||

| kilo |

The prefix "kilo" means "1,000" so one kilopascal = 1000 Pa.

|

|||||||||

|

Normal atmospheric pressure is defined as 1 atmosphere. |

||||||||||

|

Torr - |

Based on the original Torricelli barometer design, one atmosphere of pressure will force the column of mercury (Hg) in a mercury barometer to a height of 760 millimeters. A pressure that causes the Hg column to rise 1 millimeter is called a Torr (you may still see the term 1 mm Hg used; this has been replaced by the Torr). 1 atm = 760 Torr = 14.7 psi. | |||||||||

|

Bar |

(bar) The bar nearly identical to the atmosphere unit. One bar = 750.062 Torr = 0.9869 atm = 100,000 Pa | |||||||||

| Millibar (mb or mbar) |

There are 1000 millibars in one bar. This unit is used by meteorologists who find it easier to refer to atmospheric pressures without using decimals. One millibar = 0.001 bar = 0.750 Torr = 100 Pa |

|||||||||

|

Sometimes lack of pressure or flow is inconvenient - as anyone taking a

shower under a dribble can report - but other times it goes way beyond that - an

eye wash safety basis that can't flush the eyes or a fire hose that can't put

out enough water to drown a fire is useless and dangerous. |

|

Hydraulics |

2007-04-02 Rev.

| Pneumatics is the use of a gas, normally air, to apply pressure or produce movement. The advantage of pneumatic mechanisms is that they can produce reasonably fast straight line movement and moderate force with a convenient substance that does not pollute if it leaks. The disadvantage of pneumatics is that the volume required, especially for higher forces, means that hand operation is rarely possible and devices may be bulky. The fact that pneumatic devices may provide a bouncy interface may be good (cushioned) or bad (imprecise). More | Hydraulics is the use of a liquid, normally special fluid, to apply pressure or produce movement. The advantage of hydraulics is that they can apply very high forces in a small package that can be manually run. The disadvantage is that the fluids can leak and the forces may require heavy metal structures and reinforced hoses. Further, the best fluids are flammable and the least polluting fluid, water, can not be used because it will corrode many metals. Controlling the higher pressures in a system where force and movement are both needed may require complex valving. More |

| An advantage of both methods is they can produce long straight movements in a way that electrical devices can not without considerable complications such as a continuous coil for solenoids, and wires, belts and pulleys for converting rotary motion to straight with motors. | |