|

TOOLS - While it may be useful and

pleasant to have several hundred dollars in tools at hand when

working glass, it is not necessary and most glass workers have

one or more tools that is really cheap but handy and useful.

Ironically, now that I see this picture on the screen, the most

heavily used tool and most homemade is not in the picture - I

made my own jacks.

| Tool Name |

Used For |

Source |

Est. Cost

|

Official Tool Has |

Cost

|

| Needle Nose Pliers |

Pulling and twisting glass |

Found, but also hardware store. |

$10.00 |

Same |

$10.00 |

| Diamond Shears |

Cutting and shaping glass, maneuvering pipes and

punties |

ARTCO, other suppliers |

$65.00 |

Same |

$55-150 |

| Knife |

Chilling punty line for crack off |

Found |

$0.00 |

Same |

$3.00 |

| Tweezers |

Pulling glass, picking off flaws, guiding punty |

Hardware store, cheap tools bin |

$3.50 |

Bent tip |

$15.00 |

| Scissors |

Trimming glass |

Found, but hardware and grocery stores sell them |

$0.00 |

Straight Shears |

$40.00 |

| Ducknose Shears |

Trimming glass (these are sheet metal shears) |

Hardware Store |

$15.00 |

Longer Nose |

$30.00 |

| Jacks (not shown) |

Shaping Glass |

Made from flat stock |

$5+hours |

Jacks |

$120+

|

|

OUTDOOR GLASS WORKING - My equipment is

outdoors, which leads to certain problems. Some of these problems

apply to any studio that is somewhat exposed to the outdoors,

such as Art Allison's enclosed, but unheated (except by the

furnace!) place.

- BUGS - In Texas we have these mud

daubers that look like small wasps but don't sting. They

do, however, try to make a nest wherever they can,

which includes the holes in blow pipes, which they fill

with mud which dries hard. An internet discussion

suggested golf tees or small pieces of wood to block the

opening and said any location with open walls has the problem. The most obvious suggestion is to make sure the

pipe are clear before using them.

Mosquitoes are a major problem in the south, especially

with West Nile Virus around. Any container of water, like a block

bucket or crack off bucket, can show larvae. But the answer is easy -

go to a hardware store or garden center and ask for a bottle of the small

grits or granules of BT mosquito larvae control. These are sold for small

ponds, birdbaths, water gardens, etc. BT is Bacillus thuringiensis which is

a living organism that attacks wiggly larvae - it is used on worms on plants

in other subspecies. Although the bottle in front of me does not make the

claim, one brand actually said it makes the water better for birds by adding

protein.

This stuff looks like grape nuts. Instructions call for a teaspoon for every

25 square feet. Think about the size of a bucket. 5-10 granules is enough

for a bucket. In my bird feeder and block bucket outdoors, one application

is good for about two weeks. The container says 7-14 days. I usually go out

about once a week and look at all the water standing around and either add a

few granules - the bottle has a shaker top - each time or more if I see

larvae. The stuff starts to work very fast in the immediate area of

the granules - you can see the larvae start to wiggle frantically and die,

but it takes a while settle to the bottom and to drift through the water, 24

hour kill per the bottle. The stuff is also sold in blocks (Mosquito Dunks

brand from this company) but these are for ponds and a waste of money for

adding to a small container. If kept dry, the stuff lasts for years. Read

the label before you buy and contact the company involved if you have

concerns. There is a skin contact warning, but I take this to mean for the

granules, not the water with a reasonably small quantity in it. [Confirmed

by e-mail from the company]

Summit Chemical -

Mosquito Bits 2006-04-02

Wood is chewed to

shreds by various bugs, so anything on the ground must be

pressure treated. One reason for rebuilding the support

for the annealler in metal was the deterioration of the

the wood at the bottom. Pressure treated wood on and near the

ground is a partial answer.

- RAIN -

Obviously, gear needs to be more or less

protected from the weather, including rain. In addition to the discussion of temperature changes below,

insulating blanket, castable, and fire brick can absorb

water and if heated too fast the water can flash to steam

blowing apart the material. Water in blanket can so lower

the insulating value that it may take days to cook it out.

When I left the lid of my annealer askew when rewiring it

and it rained, I drilled a pair of holes in lower part of

the case and water dribbled out. In a picture above, a heating element is shown that

I use for drying out the gas heated gloryhole and furnace

to drive Obviously, gear needs to be more or less

protected from the weather, including rain. In addition to the discussion of temperature changes below,

insulating blanket, castable, and fire brick can absorb

water and if heated too fast the water can flash to steam

blowing apart the material. Water in blanket can so lower

the insulating value that it may take days to cook it out.

When I left the lid of my annealer askew when rewiring it

and it rained, I drilled a pair of holes in lower part of

the case and water dribbled out. In a picture above, a heating element is shown that

I use for drying out the gas heated gloryhole and furnace

to drive

off moisture over several hours. If the humidity

has been high or there has been a lot of rain, I pre-dry

the gloryhole. I commonly keep my annealer on and set to 90F so

that it is warmer than the outside air at night most of the year. [D

above] off moisture over several hours. If the humidity

has been high or there has been a lot of rain, I pre-dry

the gloryhole. I commonly keep my annealer on and set to 90F so

that it is warmer than the outside air at night most of the year. [D

above]

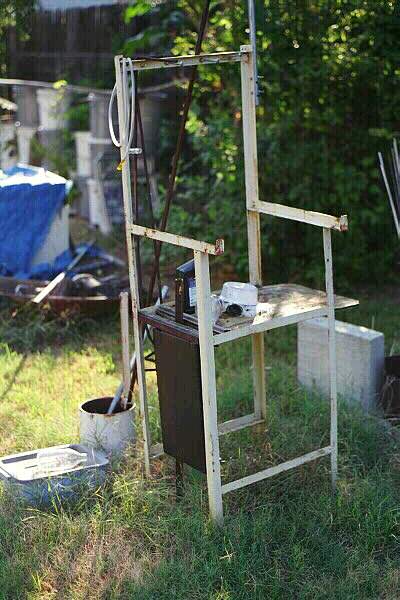

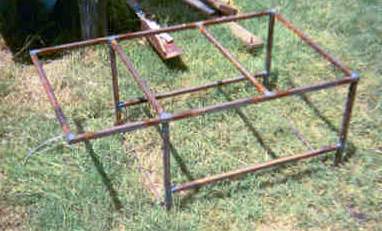

Still being used, but built earlier, is a wood frame hut, also with open

sides, [C above] This picture is from 1999 at

a time of garage reconstruction. The trees behind are now grown over

it and at one point a mass of thorny roses grew over the top - since died

and torn out. Although braced, when there was no

bottom connection,

the legs were forced out, bowing the top down, which was corrected by

jacking the center and using a ground level wire across the back. bottom connection,

the legs were forced out, bowing the top down, which was corrected by

jacking the center and using a ground level wire across the back.

At right below the glory hole door is shown a roughly bent sheet metal cover

for the yoke which protects the two ball bearing transfer units shown

here from water damages.

- TEMPERATURE CHANGES -

Obviously, when the temperature drops through freezing,

water buckets and other wet places need to be protected

or emptied. And high temperatures can melt wax used on

tools.

As the temperature rises and falls each day, equipment

can be damaged by the moisture from humidity. Part of my

annealer is rusty from this process. It happens because

the temperature inside the annealer is always "behind"

the daily temperature changes. In the evening, the inside

may be 85°F while the outside air has cooled to 60°F

with high humidity. As the air in the annealer cools and

contracts, humid air is sucked in, cooling on the metal

case and getting the whole wet. I have recently been

setting my annealer at 90°F to avoid that fluctuation,

especially into the higher humidity range.

Pipes can collect water inside and can condense moisture from the breath when cold enough. There was a thread

on this problem in cold studios, not just outdoors.

Besides corrosion that can occur, there is a risk of

being burned, because when the water drips on the hot

head, it flashes to steam which rapidly heats the pipe

for several feet back from the head. Solutions include

blowing out the pipes with compressed air, storing them

on a rack above the furnace, and having a pipe heater

that holds the pipes at an angle so air flows through

them.

- GROUND CONDITIONS -

When working outdoors, it is better to

have a concrete slab and probably better to have a

pounded bare floor (like a blacksmiths) than grass, but

Art regrets not putting a slab in his otherwise enclosed

studio because rain does blow in and the dirt gets

slippery. A slab clearly costs money and effort, although

I managed to put a slab in my garage without killing

myself. One problem with a slab is that it places clear

limits on the space and walking off the edge tain't fun (if

digging down for a ground level slab is out of the

question.) [Picture shows 5.5 x 6.5 foot raised slab

installed to get equipment out from under wood frame roof.

D] When working outdoors, it is better to

have a concrete slab and probably better to have a

pounded bare floor (like a blacksmiths) than grass, but

Art regrets not putting a slab in his otherwise enclosed

studio because rain does blow in and the dirt gets

slippery. A slab clearly costs money and effort, although

I managed to put a slab in my garage without killing

myself. One problem with a slab is that it places clear

limits on the space and walking off the edge tain't fun (if

digging down for a ground level slab is out of the

question.) [Picture shows 5.5 x 6.5 foot raised slab

installed to get equipment out from under wood frame roof.

D]

- GRASS - Looking at some of my

pictures will quickly reveal that grass grows

everywhere and cutting it is not one of my

favorite activities. And I don't like killing it

with kill-all chemicals. So I have a gasoline

powered string cutter for trimming and try to

arrange things so mowing is not incredibly

difficult. A good point of grass is that if you

drop a piece and want to, you can usually rescue

it unbroken. Several of my pieces have carbon-from-burned-grass

images on them.

- DRY GRASS - Texas has long

periods in the years with little or no rain where

the grass dries out and causes a fire hazard. I

trim more industriously and keep a garden hose

ready with a cutoff valve at the end for quick

use. I usually wet down the area around the

gloryhole first.

- SOFT GROUND - While the

dirt in our area turns to the consistency of

concrete when really dry, it absorbs water like a

sponge and it is possible to have 2" of rain

fall in the yard and have no run off. When the

ground is this soft, equipment has to be planned

for it. Even if I had a concrete slab [added in

2001], I am not sure I would mount casters

permanently on the equipment, which is heavy

enough to require costly casters that are hardly

used and will dent under the weight with time.

In any case, I build my equipment with rails at

ground level on the sides and 6" up on the

front and back. This is most easily visible on

the bench above. The side

rails provide plenty of area to keep the units

from sinking into the ground. The uniform height

of the front and back means I can either roll a

caster rig under the rails or lift the unit on to

taller casters. I have a fairly expensive set of

casters that will carry 4,000 pounds which I keep

out of the weather and to which I rig various

platforms for moving scaffolding and glass stuff.

In reality, the 6" rail height is too low

for these casters and it gets lower as the side

rails crush the dirt and grass, so I usually end

up levering the side rails up onto 2x4's before

moving. Pressure treated 1x4's or 2x4's laid flat would

reduce sinking. If I had to do a lot of moving, I would

weld up a low rig with a jack or screw built in

and get casters with wider soft wheels to avoid

sinking into the soft ground.

- AIR CONDITIONS - Air in Texas is

memorably hot and is wet more often than I like to

consider, especially in recent years. See notes on humidity & temp

changes above. When the wind is

blowing, shelter from the sun must be anchored (next). It

is also very drying, beyond the exposure to the furnace

heat, so I keep water, soda, and Gatorade on hand (buy

Gatorade in powder form - 1 gallon envelopes or bigger -

at sporting goods stores or jars on the top shelf of grocery stores to save money over bottled.) I

have a couple of floor fans that don't get much use; I

find shade is more important outdoors.

Ventilation choices

- LIGHTING - In bright sunlight, it is possible to

work with a #5 welding shield in place and still see to maneuver although

best practice suggests not. At night, background lighting is required

for safety and detail lighting helps. Overall and security lighting are

provided by a yellow high pressure sodium fixture that is very efficient and

long lasting and comes on every night automatically, giving reasonable

lighting for the whole backyard from a mount about 15' up on a conduit set

above the corner of the garage. Further area lighting is provided by a

75 watt ordinary bulb mounted on a 10' pole [f]above a (barely) moveable

concrete base; an aluminum shield guards the bulb from rain and reflects

half the light back down. Under the edge of both shelters [C

D] are bulbs,

some CFB's, just above my head, controlled by switches centrally located.

2008-04-29

- ELECTRICITY - Working outdoors demands added

steps for safety with electricity since all metal must be assumed to be

grounded and a path for a shock and when the ground is damp, that is another

path. All my electrical outlets are up under the roof of shelters just

above my head and all are fed by GFCI's. All

wiring contains a safety ground. 2008-04-29

|

a

above

a

above

Notice that the marver (m)

is hinged at one end and tools are hung

up on the rail on pegs which are just 1/4" carriage bolts (which

have large round heads. (well, that doesn't show well in the

picture right, a shield is hanging from the

rail, top right.) The bucket of wet wood, once kept on the platform, now

sits on a waist high stand after I kept getting the marver wet. To the right is a third rail

(above), on a separate stand

that holds the end of the punty while I am attaching it. The

length of the rails is based on how far my arm will stretch when

I stand and reach (I could make them longer and step forward

while rolling the pipe, but I didn't.) A pipe hanger is located

at the top right corner (see above.) Between the picture above

and the one right, the plywood panel was replaced. On the plywood

right, the white mass is frax in a Corningware bowl that is a

catcher for ornaments while the loop is added to the top. The

round tubes are for making marbles.

Notice that the marver (m)

is hinged at one end and tools are hung

up on the rail on pegs which are just 1/4" carriage bolts (which

have large round heads. (well, that doesn't show well in the

picture right, a shield is hanging from the

rail, top right.) The bucket of wet wood, once kept on the platform, now

sits on a waist high stand after I kept getting the marver wet. To the right is a third rail

(above), on a separate stand

that holds the end of the punty while I am attaching it. The

length of the rails is based on how far my arm will stretch when

I stand and reach (I could make them longer and step forward

while rolling the pipe, but I didn't.) A pipe hanger is located

at the top right corner (see above.) Between the picture above

and the one right, the plywood panel was replaced. On the plywood

right, the white mass is frax in a Corningware bowl that is a

catcher for ornaments while the loop is added to the top. The

round tubes are for making marbles.

bottom connection,

the legs were forced out, bowing the top down, which was corrected by

jacking the center and using a ground level wire across the back.

bottom connection,

the legs were forced out, bowing the top down, which was corrected by

jacking the center and using a ground level wire across the back.