|

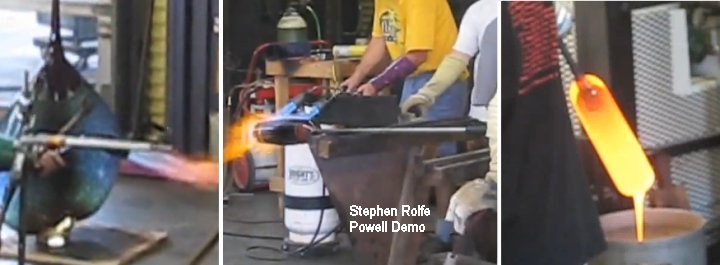

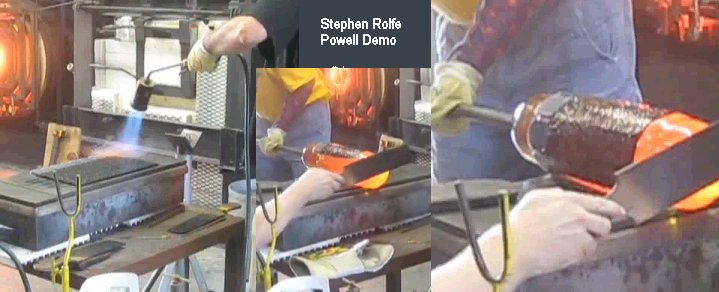

This page shows various pieces of glass created from furnace glass and discusses possible or actual techniques for making them. Some of the glass is commercial and therefore the actual technique may not be known. |

2003-06-05 Posted by MF to Yahoo Glass discussion WORKING ALONE -Picture at right showing my bench and its

third arm.

[benches] The 3rd arm is a freestanding box with a ring into which I dump my hot

punties and pipes, but it also has an adjustable height right angle that is

matched to the arms on my bench. There is a pipe hanger which is a V fold of metal above the

bench.

WORKING ALONE -Picture at right showing my bench and its

third arm.

[benches] The 3rd arm is a freestanding box with a ring into which I dump my hot

punties and pipes, but it also has an adjustable height right angle that is

matched to the arms on my bench. There is a pipe hanger which is a V fold of metal above the

bench.Transfer goes like this: Chill the jack line, reheat the bottom, hang the piece, grab a hot punty, gather the bit, marver, blunt and chill the end; lay the punty down on the middle arm with the bit to the left using the right hand while grabbing the hanging pipe with the left and pivot it down left to the piece is to the right. With the right hand, pick up the diamond shears and with tips, pick up the punty near the bit, sliding it to the right to get it out beyond the piece; use the left hand to roll the piece, bend over and spot the center and slide the hot bit into place; adjust the punty to center (you didn't think I hit center every time did you?); change hands with the shears and take the punty in the right, squeeze the jack line with the shears (wet or not), test the punty - I tend to be hot, so it has time to cool, set the jack line on the arm edge, tap the glass twice with the edge of the shears and whack the pipe about 6-8" down. When it breaks successfully, set the shears down while controlling the piece on the punty and if time, grab the pipe and drop it into the bucket under the 3rd arm. Simple, unh! |

| ONE GATHER -

I keep working on thinner, etc. People who do pieces with 1 gather have

the following tricks - relatively cool glass in the furnace, a bigger head on

the pipe - some goblet makers use a 1.5" head on a .75" pipe. If you recall my setup, my yoke has the transfer balls attached in a V cut in a steel panel which acts as a heat shield very nicely. But it also means that there is a flat surface on either side of the V, so I can lay the pipe in the V and roll it easily and lay a hot bit on a punty in one of the rough notches (it was torch cut when I was learning) on the top and roll it there. Thus I can reheat piece and punty for another attempt at transferring to a punty or I can reheat a color or clear gather being used to add a hot bit or stringer to the piece. With a standard yoke, I have seen solo workers cross the pipe with the punty, so the punty is laying on the pipe near the moile. This requires the door be open more or be bigger. |

| Making: Goblets Where: CraftWeb discussion Special Equipment: None 2002-09-21 In a discussion running on CraftWeb, guys who make goblets say that having the glory hole relatively cold gives more time for working the piece without the bowl collapsing. 2003-07-02 In another discussion of making goblet feet, several points are made. Four hours of just making feet on stems on a punty (no bowls) will insure perfection of whatever method is used. Besides the wooden footer, and the fancy tool from Emenese, one person is reported using a small (3x5) thin (1 sheet) newspaper pad with success. Several people form a gather made on the stem itself, no cookie. If using a cookie, reheat to the softest that can be handled and really squeeze it down while turning quickly.

|

These two sets of pieces were photographed at Elliott's

Hardware, where I work. Each is an example, I think, of the best

that can be produced by low cost, mass production hand made

techniques, unfortunately by low paid people. The colored vases require gathering a small amount of color and gathering a

larger amount of clear, and doing the initial forming. The bubble

in the bottom was almost certainly formed with a simple centered

mold with a blunt spike (because of its size and uniformity.)

Then another gather of clear over the indention to form the

bubble and final forming of the glass. Both of these sets of

pieces have ground tops, which means they are probably not

transferred to a punty and not reheated. The square vases are

clearly mold blown and have no bubble in the bottom. Another vase

like the ones on the left has a round top and four lobed base,

the base being formed by letting the hot glass flow between four

steel pegs. These two sets of pieces were photographed at Elliott's

Hardware, where I work. Each is an example, I think, of the best

that can be produced by low cost, mass production hand made

techniques, unfortunately by low paid people. The colored vases require gathering a small amount of color and gathering a

larger amount of clear, and doing the initial forming. The bubble

in the bottom was almost certainly formed with a simple centered

mold with a blunt spike (because of its size and uniformity.)

Then another gather of clear over the indention to form the

bubble and final forming of the glass. Both of these sets of

pieces have ground tops, which means they are probably not

transferred to a punty and not reheated. The square vases are

clearly mold blown and have no bubble in the bottom. Another vase

like the ones on the left has a round top and four lobed base,

the base being formed by letting the hot glass flow between four

steel pegs. The pieces on the right were probably made in two sections, the

top being mold blown and then inflated, while the foot and stem

were molded and attached hot. Again, the piece has a ground lip.

It was either annealed on the pipe or cracked off well above the

lip line. 2000-11-06. The pieces on the right were probably made in two sections, the

top being mold blown and then inflated, while the foot and stem

were molded and attached hot. Again, the piece has a ground lip.

It was either annealed on the pipe or cracked off well above the

lip line. 2000-11-06.

Notes on how a team might make bottles in production situation, written down for woman who was asked to make 12,000 750ml bottle twice a year. on CraftWeb

|

| TRIM THE RIM - I have been told that one of the most difficult things to do is to thin out the lip by pulling the lip and trimming if it is too thick. After freeing the piece from the pipe, the rim may be to thick if jacked in the wrong place or if not blown out at the jack line. If you heat the lip hot, you can take tweezers or diamond shears and pull it lengthwise in several places - this will give you a thinner, ragged edged lip, which you reheat. Then using cutting shears, you start cutting at the bottom, turning the bottom toward you, so the peel falls down and away from the glass. If you are quick, it can be done in one move, but more likely you will feel the glass harden under the shear blades, so you will turn and cut off the peel, letting it fall to concrete floor or metal pan and reheat the rim to finish the cut. On the next reheat the cut edge will smooth and if evenly done, spinning or shaping will be much easier than fighting with the thick glass. 2007-04-20 |

|

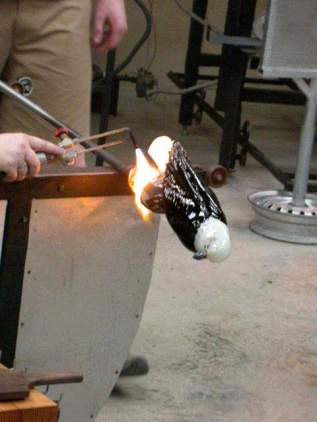

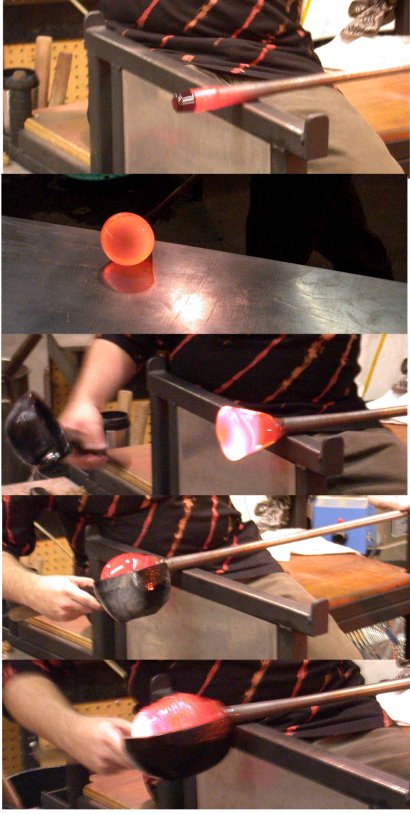

Making: Classic bubble on bubble goblet

|

|

Making: Flat sided pieces The sequence of images of the Marilee Moore demo (below) starts with a picture of her using cork pads to flatten the piece. A piece can also be flattened or given multiple sides by letting it sag onto the marver, lifting and rotating 180, 120, or 90 degrees for 2, 3, or 4 sides, and laying it down again. 2006-07-22

|

Making:

Making: