| The purpose of this page is to make a reference to those

images used on my site which were scanned from the book: The Glass Gaffers

of New Jersey and their creations from 1789 to the present, Adeline Pepper,

Charles Scribner's Sons, NY, 1971, ISBN 684-10459-8 [LC#70-123831 748 P424g

Dallas Pub. Lib. Downtown] which are used on this site under

fair

use copyright law-link |

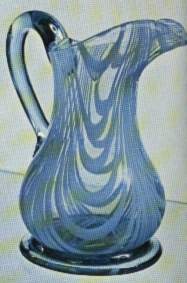

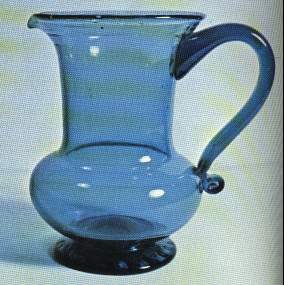

Plate 7 Sapphire Blue,

distinctive Jersey Color, applied crimped foot, "matchless

design" opp.p85 Plate 7 Sapphire Blue,

distinctive Jersey Color, applied crimped foot, "matchless

design" opp.p85 |

Fig. 51 Early Jersey

Candlestick double -baluster, with gadrooning. p.78 Fig. 51 Early Jersey

Candlestick double -baluster, with gadrooning. p.78 |

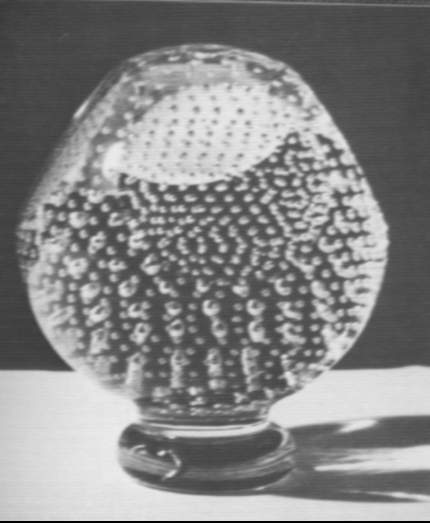

Pl.14 Opp.p.180

Millville. Dragon fire (the color inside) mantle ornament. Spikes

of color coming to surface. Originally not sure how it was done,

after looking at spherical weights (Pl.16.opp.p260) and using my

memory, color bits on the bottom of the clear glass are pierced

with a long thin tool, carrying the color up into the clear in a

slender spike - with air in the spike originally. Clearly this

shape was extensively worked after the piercing. Pl.14 Opp.p.180

Millville. Dragon fire (the color inside) mantle ornament. Spikes

of color coming to surface. Originally not sure how it was done,

after looking at spherical weights (Pl.16.opp.p260) and using my

memory, color bits on the bottom of the clear glass are pierced

with a long thin tool, carrying the color up into the clear in a

slender spike - with air in the spike originally. Clearly this

shape was extensively worked after the piercing.

|

Brown/purple goblet, double gather on the bottom of the bowl Brown/purple goblet, double gather on the bottom of the bowl |

A mold blown bottle of an Indian to advertise the product. Fig.

27 "The Indian Queen" p.38

A mold blown bottle of an Indian to advertise the product. Fig.

27 "The Indian Queen" p.38 |

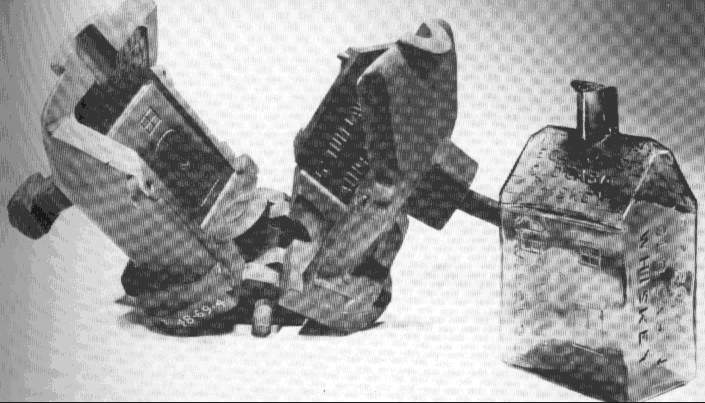

A split mold

and the bottle made with it - note diagonal split (corner to

corner) Fig. 30 Booz Bottle and iron mold used at Whitney Glass

Works Glassboro, about 1860. A split mold

and the bottle made with it - note diagonal split (corner to

corner) Fig. 30 Booz Bottle and iron mold used at Whitney Glass

Works Glassboro, about 1860.

|

Stiegel-type flasks, inverted

diamond pattern Emil J. Larson 1930s. Amethyst netted bottle opp.

p 116 Stiegel-type flasks, inverted

diamond pattern Emil J. Larson 1930s. Amethyst netted bottle opp.

p 116 |

|

|

| Whitney Bros. Glassworks, Glass House NJ, in the late 1870's

"dominated the down, with four 2-story factory buildings

each 100 by 80 feet and there were the usual appendages of

sawmill, box factory, packing house, warehouses, wheelwright and

blacksmith shops. ... Glass blown each month amounted to 525

tons, a job handeled by some 400 employees. A monthly supply of

100 tones of soda ash, 300 tons of sand, and 2,000 bushels of

oyster-shell lime were required to produce this glass." p.

37 Solomon H. Stanger, Glassmaker 1842-52, "The most steadily employed blower was George C. Hewitt, who over the course of 40 months recorded [in a ledger 1848-52] blew 22,680 bottles, for which he received $3,148.99. This was at a time when house rent was $6.25 for three months and firewood was $2.75 a cord." "For the blast of 1848-49 there were 133 different types and sizes of bottles, from vials to demijohns, from jelly to pickle jars, from oval inks to 'plain old.'" p.44 1843 "'Dyott's Mixen for Flint Glafs' "The union allowed workers to blow only 40 feet of single strength glass a week or 30 feet of double strength (it took 11 pains of single strength and 6 pains of double to equal an inch. ... Blowers here worked 7-8 hours then rested for 16 while the next batch was melted [until continuous furnaces were introduced.] Cylinders of glass were sometimes 70 inches long." GGNJ p. 101 "At a peak in its progress - 1883 - the Williamstown Glass Company did a quarter-million dollars worth of business annually. To achieve this the firm bought 5,000 tons of coal, 2,800 tons of sand, 1,000 tons of soda-ash, 4,000 tons of cordwood, 23,000 bushels of lime and 1,500,000 feet of box-boards a year." p. 151 [MF a US bushel is "2150.42 cubic inches or about 1.2445 cubic feet, and represents the volume of a cylindrical container 18.5 inches (47.0 cm) in diameter and 8 inches (20.3 cm) deep. The U. S. bushel holds about 35.239 07 liters." http://www.unc.edu/~rowlett/units/dictB.html ] |

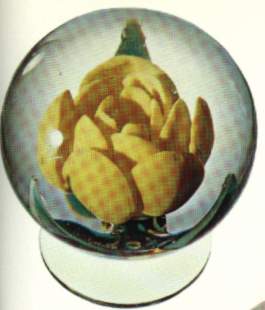

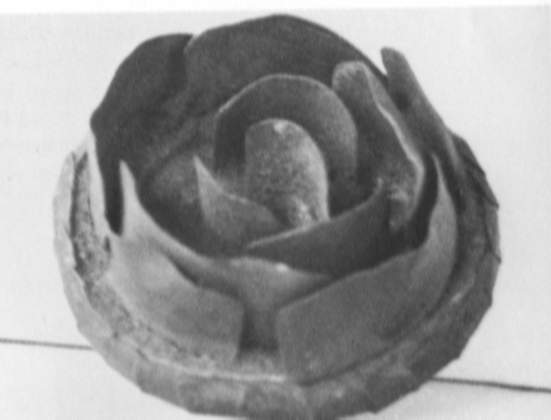

Fig.192 Ralph

Barber's Crimp, modeled after rose shown on pottery in fig. 191

According to book, Barber also used the Rhulander Crimp below Fig.192 Ralph

Barber's Crimp, modeled after rose shown on pottery in fig. 191

According to book, Barber also used the Rhulander Crimp below

|

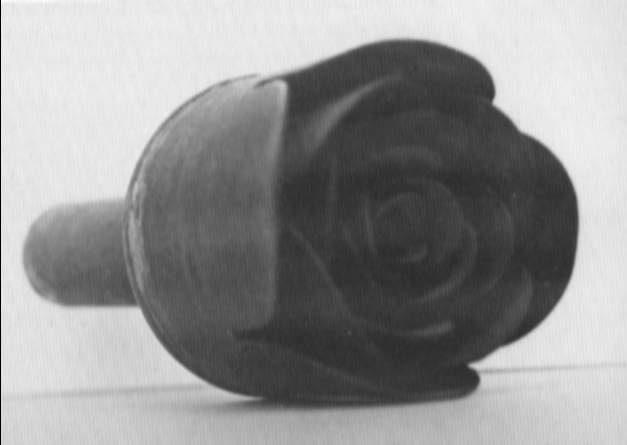

Fig. 199, p.263 Crimp used by

John Rhulander, described as more formal. Fig. 199, p.263 Crimp used by

John Rhulander, described as more formal.

|

p.321 Map of NJ showing

various glass making towns discussed in the book. |