|

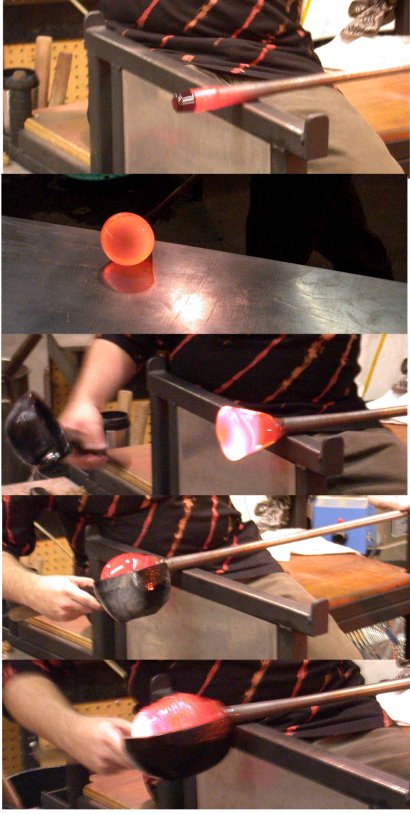

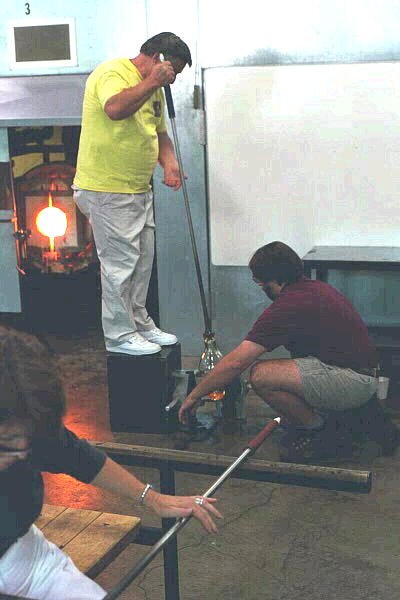

In manipulating hot glass, many of the tools are made of

metal, now usually stainless steel, iron in the past, but many

are made of wood and paper. There is a kind of jack that uses

rolls of paper or wood dowels for the ends and blocks of wood are

used to make, well, blocks as well as molds. Almost always, these

flammable materials are soaked in water before use and the layer

of steam from the water helps preserve the material. |

|

NEWSPAPER Taking the ends of the shape, fold at about the 1/3 points (C) further bending the narrower end (D) to fit it inside the other end and tucking it in and patting it flat. After forming the pad, cut the corners off (E) which allows much more flexibility in shaping the wet pad to the shape of the hand. Soak in water and keep wet by putting a handful of water from the block bucket or by squirting from a handy water bottle. The pad is used by shaping it to the hand and cupping it around the glass. Normally, once shaped, it is laid on the bench face up and water is added as mentioned above. The New York Times is legendary for being the best newspaper for working glass. "Bad" paper turns to pulp when wet, while "good" paper retains its shape and layers. Paper V-Block - Wet newspaper is placed in a V made of two boards nailed edge to edge with a triangle of board filling one end. The paper is molded to shape and used wet to blow cylinders with the pipe and glass aligned to the length of the V. "Like having 6-8 hands to block with newspaper." (CraftWeb) 2007-11-24 Paper Marver - Wet paper, 10-15 sheets, is laid on a flat surface to roll

glass in place, primarily cylinders. Lasts a month or so. Reasonably damp, not

too wet. |

|

PAPER WOOD |

The simplest tool for

maneuvering hot glass is wet newspaper. The pad is created by

taking 2-5 full sheets of newspaper (the number depending on

personal choice) laying them down as if reading the full front

page. Fold the sides in (A) so they overlap and the fold is on

top (B). This makes a long narrow shape. (If using tabloid style

paper, use it with pages open as if reading inside.) It helps if one end is somewhat

narrower than the other.

The simplest tool for

maneuvering hot glass is wet newspaper. The pad is created by

taking 2-5 full sheets of newspaper (the number depending on

personal choice) laying them down as if reading the full front

page. Fold the sides in (A) so they overlap and the fold is on

top (B). This makes a long narrow shape. (If using tabloid style

paper, use it with pages open as if reading inside.) It helps if one end is somewhat

narrower than the other.

Below the picture of the cutters is a montage of a block of cherry

with marble marver holes on one side and a groove on the other side. The

groove was cut by first drilling a series of bigger holes down about 1/3 deep

then 1/2" holes centered on the big ones of about the right depth. Then

the wide cutter mounted in a drill press was used to clear out the U shape in

several passes. 2007-02-04

Below the picture of the cutters is a montage of a block of cherry

with marble marver holes on one side and a groove on the other side. The

groove was cut by first drilling a series of bigger holes down about 1/3 deep

then 1/2" holes centered on the big ones of about the right depth. Then

the wide cutter mounted in a drill press was used to clear out the U shape in

several passes. 2007-02-04

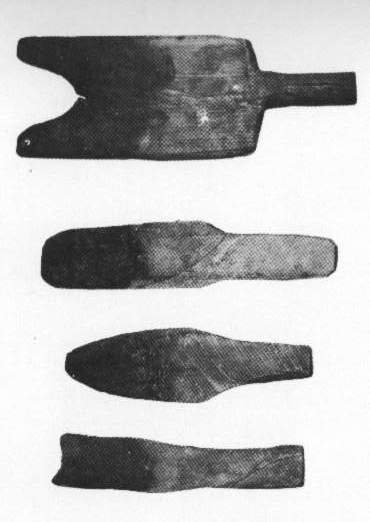

Paddles are

used to shape the glass, especially for a flat bottom and for

shielding the arms and hands of the gaffer while working large

pieces. When a piece is turning on the bench and a paddle is held

against the bottom a smooth flat bottom with a slight indentation

in the center usually occurs.

Paddles are

used to shape the glass, especially for a flat bottom and for

shielding the arms and hands of the gaffer while working large

pieces. When a piece is turning on the bench and a paddle is held

against the bottom a smooth flat bottom with a slight indentation

in the center usually occurs.

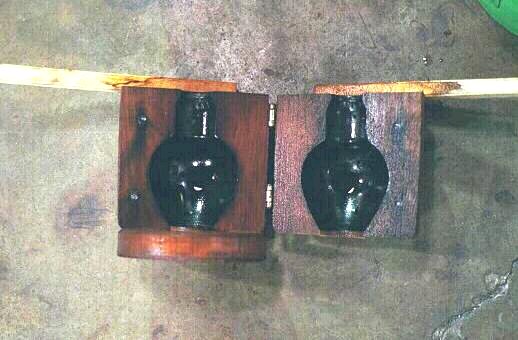

These

two pieces were glued up for specific purposes.

These

two pieces were glued up for specific purposes.