|

Pressed glass involves a glob of molten glass being pushed

into a mold. The mold may be the full shape of the glass so it is

pressed flat into the mold or it may be an outline of the piece

so a plunger is pressed into the glob (forming the inside of the

piece) so it flows up against the inside of the mold - the plunger

must be shaped to pull out, so pressed glass that is not further

worked will always taper out, but a basic vase shape may be worked in, provided

a lip and handle to make a pitcher or worked out to a bowl or platter shape.

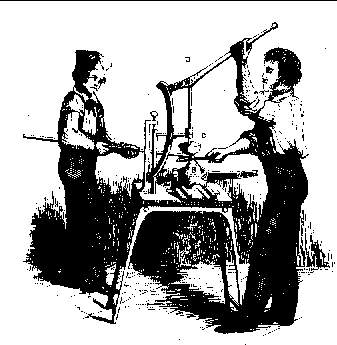

(Manual pressing right) Examples Pressed glass involves a glob of molten glass being pushed

into a mold. The mold may be the full shape of the glass so it is

pressed flat into the mold or it may be an outline of the piece

so a plunger is pressed into the glob (forming the inside of the

piece) so it flows up against the inside of the mold - the plunger

must be shaped to pull out, so pressed glass that is not further

worked will always taper out, but a basic vase shape may be worked in, provided

a lip and handle to make a pitcher or worked out to a bowl or platter shape.

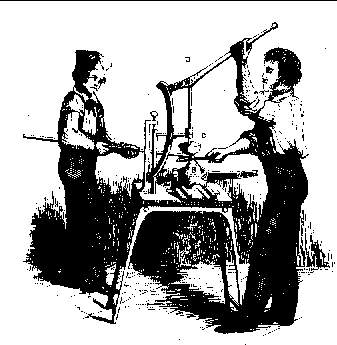

(Manual pressing right) Examples

Pressed glass is also used to produce bits used on other pieces, including

the foot and stem for a mold blown goblet, handles, knobs, lids, etc. A

technique called mold pressed involves a

small mold being pushed into a blob of molten

glass, either on the object or as a cookie that is applied to the piece.

Common pressings include flowers, rosettes, lion's heads and strawberry

prunts.

Pressed glass objects that are not variations on blown objects

include sun catchers, square or disk feet for goblets, paper

weights or logo displays for desks.

Circa 1911: Pressing of containers is done with an iron mold mounted in a

stand with an arm across the top from which the presser hangs.

Raising the arm clears the mold to add glass, the presser being

placed and pushed down by the weight of the person pulling on the

arm plus the leverage. In pictures the overhead arm appears to be

about 6 feet off the floor. Major skill factors are having the right

amount of glass put in the mold at the right temperature.

Circa 1911: Pressing of containers is done with an iron mold mounted in a

stand with an arm across the top from which the presser hangs.

Raising the arm clears the mold to add glass, the presser being

placed and pushed down by the weight of the person pulling on the

arm plus the leverage. In pictures the overhead arm appears to be

about 6 feet off the floor. Major skill factors are having the right

amount of glass put in the mold at the right temperature.

Further information on old techniques may be found in my scan of the 1911

Encyclopedia Britannica,

page 97

|