|

|

|

Steward

Observatory Mirror Laboratory

The University of Arizona Steward Observatory Mirror Lab uses fusing techniques to make lightweight but very large astronomical mirrors (5-8 meters). A mold is used to make a honeycomb back. The top of the mold is curved to the shape of the mirror and is built in a kiln that spins (at 7 rpm) at the rate that makes the glass curve to a bowl shape that matches the mold, thus making a thin layer. Chunks of Pyrex-type glass, 30,000 pounds+, are placed on the mold and melted. The inside of the lid of the mold, 8 meters, 25+ feet, 300 inches, across. Both melts the glass and anneals. For a much shorter time (under 2 months) than poured mirrors (months and months)

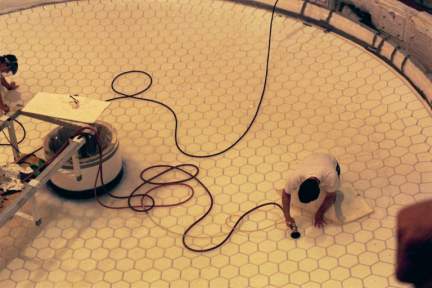

Top of the mold with a layer of glass in place and a person working on it. In this case, the mold leaked, dropping several thousand pounds of glass into the base and leaving a very thin layer. They are going to add more glass, take hours to get it up to annealing temp then fire the top to melt the top but not the sides to save the mirror. The men are grinding off bubbles and other defects.

Some of the hardware in the mirror lab. In the far background a smaller (5.5 meter) mirror is having its back ground for a smooth surface before the front is finally smoothed. In the foreground, is the housing for a mirror, which includes the mounting ring and the plumbing that quickly brings the mirror to air temperature when the dome is opened and also allows fine tuning the curve with differential air flow.

|