EB GLASS p.87

reduction to the ferrous state. Lead gives a pale yellow

colour. Silver oxide, mixed as a paint and spread on the surface

of a piece of glass and heated, gives a permanent yellow

stain. Finely divided vegetable charcoal added to a soda-lime

glass gives a yellow colour. It has been suggested that the

colour is due to sulphur, but the effect can be produced with a

glass mixture containing no sulphur, free or combined, and by

increasing the proportion of charcoal the intensity of the colour

can be increased until it reaches black opacity. Selenites and

selenates give a pale pink or pinkish yellow. Tellurium appears

to give a pale pink tint. Nickel with a potash-lead glass gives a

violet colour, and a brown colour with a soda-lime glass. Copper

gives a peacock-blue which becomes green if the proportion of the

copper oxide is increased. If oxide of copper is added to a glass

mixture containing a strong reducing agent, a glass is produced

which when first taken from the crucible is colourless but on

being reheated develops a deep crimson - ruby colour. A similar

glass. if its cooling is greatly retarded, produces throughout

its substance minute crystals of metallic copper, and closely

resembles the mineral called aventurine. There is also an

intermediate stage in which the glass has a rusty red colour by

reflected light, and a purple- blue colour by transmitted light.

Glass containing gold behaves in almost precisely the same way,

but the ruby glass is less crimson than copper ruby glass. J. E.

C. Maxwell Garnett, who has studied the optical properties of

these glasses, has suggested that the changes in colour

correspond with changes effected in the structure of the metals

as they pass gradually from solution in the glass to a state of

crystallization.

Owing to impurities contained in the materials from which

glasses are made, accidental coloration or discoloration is often

produced. For this reason chemical agents are added to glass

mixtures to remove or neutralize accidental colour. Ferrous oxide

is the usual cause of discoloration. By converting ferrous into

ferric oxide the green tint is changed to yellow, which is less

noticeable. Oxidation may be effected by the addition to the

glass mixture of a substance which gives up oxygen at a high

temperature, such as manganese dioxide or arsenic trioxide. With

the same object, red lead and saltpetre are used in the mixture

for potash-lead glass. Manganese dioxide not only acts as a

source of oxygen, but develops a pink tint in the glass, which is

complementary to and neutralizes the green colour due to ferrous

oxide.

Glass is a bad conductor of heat. When boiling water is poured

into a glass vessel, the vessel frequently breaks, on account of

the unequal expansion of the inner and outer layers. If in the

process of glass manufacture a glass vessel is suddenly cooled,

the constituent particles are unable to arrange themselves and

the vessel remains in a state of extreme tension. The surface of

the vessel may be hard, but the vessel is liable to fracture on

receiving a trifling shock. M. de la Bastie's process of "toughening

glass consisted in dipping glass, raised to a temperature

slightly below the melting-point, into molten tallow. The surface

of the glass was hardened, but the inner layers remained in

unstable equilibrium. Directly the crust was pierced the whole

mass was shattered into minute fragments. In all branches of

glass manufacture. the process of "annealing," i.e.ˇ

cooling the manufactured objects sufficiently slowly to allow the

constituent particles to settle into a condition of equilibrium,

is of vital importance. The desired result is obtained either by

moving the manufactured goods gradually away from a constant

source of heat, or by placing them in a heated kiln and allowing

the heat, gradually to die out.

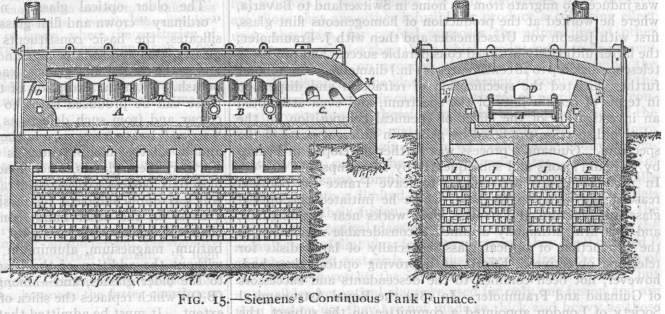

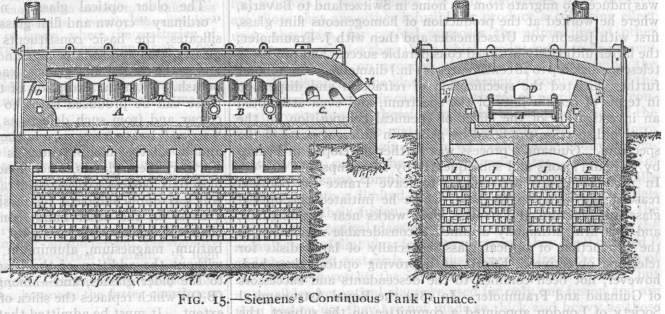

The furnaces (FIG. 15) employed for melting glass are usually

heated with gas on the "Siemens", or some similar system of

regenerative heating. In the United States natural gas is used

wherever it is available. In some English works coal is still

employed for direct heating with various forms of mechanical

stokers. Crude petroleum and a thin tar, resulting from the

process of enriching water-gas with petroleum, have been used

both with compressed air and with steam with considerable success.

Electrical furnaces have not as yet been employed for ordinary

glass-making on a commercial scale, but the electrical plants

which have been erected for melting and moulding quartz suggest

the possibility of electric heating being employed for the

manufacture of glass. Many forms of apparatus have been tried for

ascertaining the temperature of glass furnaces. It is usually

essential that some parts of the apparatus shall be made to

acquire a temperature identical with the temperature to be

measured. Owing to the physical changes produced in the material

exposed prolonged, observations of temperature are impossible. In

the Féry radiation pyrometer this difficulty is obviated, as the.

instrument may be placed at a considerable distance from the

furnace. The radiation passing out front an opening in. the

furnace falls upon a concave mirror in a telescope and is focused

upon a thermoelectric couple. The hotter the furnace the greater

is the rise of temperature of the couple. The electromotive force

thus generated is measured by a galvanometer, the scale of which

is divided and figured so that the temperature may be directly

read. (See THERMOMETRY.)

The furnaces (FIG. 15) employed for melting glass are usually

heated with gas on the "Siemens", or some similar system of

regenerative heating. In the United States natural gas is used

wherever it is available. In some English works coal is still

employed for direct heating with various forms of mechanical

stokers. Crude petroleum and a thin tar, resulting from the

process of enriching water-gas with petroleum, have been used

both with compressed air and with steam with considerable success.

Electrical furnaces have not as yet been employed for ordinary

glass-making on a commercial scale, but the electrical plants

which have been erected for melting and moulding quartz suggest

the possibility of electric heating being employed for the

manufacture of glass. Many forms of apparatus have been tried for

ascertaining the temperature of glass furnaces. It is usually

essential that some parts of the apparatus shall be made to

acquire a temperature identical with the temperature to be

measured. Owing to the physical changes produced in the material

exposed prolonged, observations of temperature are impossible. In

the Féry radiation pyrometer this difficulty is obviated, as the.

instrument may be placed at a considerable distance from the

furnace. The radiation passing out front an opening in. the

furnace falls upon a concave mirror in a telescope and is focused

upon a thermoelectric couple. The hotter the furnace the greater

is the rise of temperature of the couple. The electromotive force

thus generated is measured by a galvanometer, the scale of which

is divided and figured so that the temperature may be directly

read. (See THERMOMETRY.)

In dealing with the manufacture of glass it is convenient to

group the various branches in the following manner:

| |

Manufactured Glass. |

|

| |

I. Optical Glass |

|

| |

II. Blown Glass |

|

| A. Table glass |

B. Tube.

|

C. Sheet |

D. Bottles. |

| |

Special glasses

for thermo-

meters, and

other special

glasses.

|

and crown glass.

|

|

| |

III. Mechanically Pressed

Glass |

|

| A. Plate and rolled plate glass |

B. Pressed table glass |

|

| |

|

|

|

I. OPTICAL GLASS. As regards both mode of production and

essential properties optical glass differs widely from all other

varieties. These differences arise primarily from the fact that

glass for optical uses is required in comparatively large and

thick pieces, while for most other purposes glass is used in the

form of comparatively thin sheets; when, therefore, as a

consequence

The furnaces (FIG. 15) employed for melting glass are usually

heated with gas on the "Siemens", or some similar system of

regenerative heating. In the United States natural gas is used

wherever it is available. In some English works coal is still

employed for direct heating with various forms of mechanical

stokers. Crude petroleum and a thin tar, resulting from the

process of enriching water-gas with petroleum, have been used

both with compressed air and with steam with considerable success.

Electrical furnaces have not as yet been employed for ordinary

glass-making on a commercial scale, but the electrical plants

which have been erected for melting and moulding quartz suggest

the possibility of electric heating being employed for the

manufacture of glass. Many forms of apparatus have been tried for

ascertaining the temperature of glass furnaces. It is usually

essential that some parts of the apparatus shall be made to

acquire a temperature identical with the temperature to be

measured. Owing to the physical changes produced in the material

exposed prolonged, observations of temperature are impossible. In

the Féry radiation pyrometer this difficulty is obviated, as the.

instrument may be placed at a considerable distance from the

furnace. The radiation passing out front an opening in. the

furnace falls upon a concave mirror in a telescope and is focused

upon a thermoelectric couple. The hotter the furnace the greater

is the rise of temperature of the couple. The electromotive force

thus generated is measured by a galvanometer, the scale of which

is divided and figured so that the temperature may be directly

read. (See THERMOMETRY.)

The furnaces (FIG. 15) employed for melting glass are usually

heated with gas on the "Siemens", or some similar system of

regenerative heating. In the United States natural gas is used

wherever it is available. In some English works coal is still

employed for direct heating with various forms of mechanical

stokers. Crude petroleum and a thin tar, resulting from the

process of enriching water-gas with petroleum, have been used

both with compressed air and with steam with considerable success.

Electrical furnaces have not as yet been employed for ordinary

glass-making on a commercial scale, but the electrical plants

which have been erected for melting and moulding quartz suggest

the possibility of electric heating being employed for the

manufacture of glass. Many forms of apparatus have been tried for

ascertaining the temperature of glass furnaces. It is usually

essential that some parts of the apparatus shall be made to

acquire a temperature identical with the temperature to be

measured. Owing to the physical changes produced in the material

exposed prolonged, observations of temperature are impossible. In

the Féry radiation pyrometer this difficulty is obviated, as the.

instrument may be placed at a considerable distance from the

furnace. The radiation passing out front an opening in. the

furnace falls upon a concave mirror in a telescope and is focused

upon a thermoelectric couple. The hotter the furnace the greater

is the rise of temperature of the couple. The electromotive force

thus generated is measured by a galvanometer, the scale of which

is divided and figured so that the temperature may be directly

read. (See THERMOMETRY.)