| Drew makes millefiori weights, either very formal ones,

which sell in the $350-700 price range or smaller informal ones which use

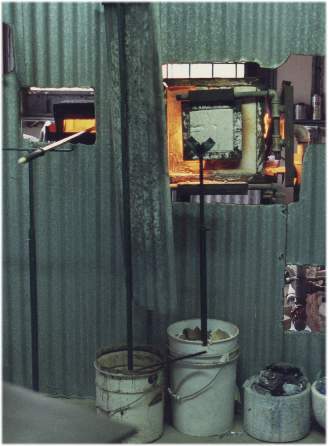

the same cane, but in a scattered pattern. This is his basic marver set up.

The marble slab is literally the source of the word marver from the Italian.

He puts his color bits on the marble. The cup in the middle of the steel

marver is one of the weight setup cups, another is on the hot plate at the

bottom of the picture. Each cup is a ring with a matching disk having a

machined groove to hold the ring in place. |

|