|

Choices in Heating a Furnace/Glory Hole Rev. 3/27/94, 12/14/94,

7/18/95

ELECTRICITY VS GAS - For a furnace or glory hole for

glassblowing, a burner is normally used as it is much usually more

economical (when element cost is included) to use gas over

electricity. Those people using electricity to melt glass report

that the size of the furnace must be limited* and the elements

must often be replaced each time the furnace is shut down. Since

the temperature of melted glass is very near the upper limit* of

most electric heating material (except carbon arc which requires

such complicated hardware no artist uses it) or silicon oxide rod

which requires heavy power) the elements must be heavy and well

supported. Being heavy means that higher power and current must

be provided, adding to the expense.

[*I have learned recently that

Silicon Carbide elements, while suitable for high temps, require

adjustment of the voltage during the life of the elements,

increasing it to maintain power because the resistance changes so

much with aging and require lower voltage to start with (60 volts.) adding

complications, but becoming lower in cost and removing the size and temperature

limits.. 2006-05-30]

HEAT SUPPLIED - Burners supplying 90,000 Btu up to 350,000 Btu

are be used. A British thermal unit (Btu) is the amount of heat

needed to raise one pound of water one degree Fahrenheit. (about

1055 Joules in metric, 1055 watt-seconds) A common kitchen gas

burner is about 8,000 Btu, the large "Super Burner" on

our stove is 18,000. Turkey fryers blast off at 140,000-180,000 Btu. Wok

burners are 16,000-40,000 Btu. 2006-11-30

BASIC BURNER OVERVIEW - For the burner to work fuel must be

mixed with air. Since glass melting often takes place for months

on end, safety features must be considered, including dealing

with rare gas and more common electric power failures

Normally, the glory hole is heated only while the glass is

being worked and most often has manual controls, including a way

to produce a reducing atmosphere for striking, most often just

cutting off the air for a while.

Most of the considerations that apply to ceramics kilns also

apply to glass furnaces, such as spacing away from building walls.

But ceramic kilns are usually fired up to a temperature and then

shut down, while furnaces are often left at the holding

temperature (equal to cone 6 - 2100°F) for days and, when batch

is cooked, are maintained overnight at equivalent to cone 10-11 (2400-2500°F.)

|

|

COMBUSTION TRAIN - The entire flow of fuel to the burner, in a code approved

arrangement, is prescribed by one or more standards from National Fire

Protection Association (NFPA) industrial safety. Wading through the standards

involves eliminating a lot of stuff that applies only to relatively low

temperature burners - boilers and cooking ovens. Most suppliers of industrial

burners will work with the buyer to design a safe package, given the Btu

requirements, with the result costing $1500-2500 per burner train.

- WARNING-THIS IS NOT COMPLETE, DO NOT RELY ON IT FOR

DESIGN, IT IS AN OVERVIEW FOR GENERAL INFORMATION ONLY.

- At the fuel entry to the space (and/or at the tank) is a

manual cutoff valve which can easily be reached at all

times.

- At each branch to a burner there is a manual cutoff for

maintenance, etc. It is best if this is quickly

accessible. Some studios put in at the front of the hot

wall for quick access, especially for glory holes.

- For each burner there is a remotely driven (pneumatic or

electrical) valve that can provide cutoff of fuel. This

may be part of a valve that controls gas flow for

temperature control.

- There are one or more regulators that reduce pressure

from the main line to that useable by the burner.

- There may be a high and low pressure sensor to determine

if the gas is behaving.

- There may be gas/air mixer that proportions the two.

Mixers are available that once set, allow changing the

air flow and they will automatically keep the gas

properly flowing, about $200.

- At the burner, a flame sensor. This is totally vital

where the flame is shut off and turned back on later, as

in boilers, which require that all the gas be blown out

of the heating chamber before re-ignition is tried.

- At the burner, an igniter. Yes, a lot of furnaces and

glory holes are lighted with a burning piece of

newspaper, but if the furnace is to be left alone, it

probably has to have relighting ability.

- At the furnace, a temperature sensor. If the temperature

is to be controlled, a thermocouple or RTD is required.

It may also be used to determine whether a restart is

possible if an igniter has been left out of the setup. If

the furnace is hot enough to light the gas, the gas is

turned on, otherwise not, and the furnace chills down,

probably breaking the pot.

- A controller, to tie everything together. It is possible

to go both directions: a lesser setup where hard wired

sensors turn off valves or a greater setup where a

serious industrial controller handles the temperature and

the startup and the safety issues. A middle ground is one

simple controller that handles the temperature and

another fairly simple controller that handles safety and

restart.

|

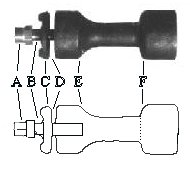

A wasp waist tube with the gas inlet appropriately placed drags

air proportionate to gas pressure. The wasp waist and gas velocity lowers air

pressure to drag more air in. Used with high pressure gas. No blower.

A wasp waist tube with the gas inlet appropriately placed drags

air proportionate to gas pressure. The wasp waist and gas velocity lowers air

pressure to drag more air in. Used with high pressure gas. No blower.